After putting the gondola together, we spent some time preparing for electrical integration with the cryostat. Mostly this took the form of a "solder party" in which we made cables for several days. There are some other random bits too.

These photos sat on my computer for a little while before I got around to posting them.

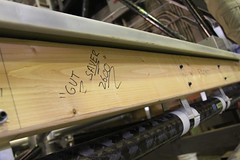

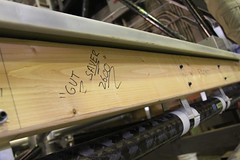

Drilling the floor mounts...

...to installl the "Gut Saver 2600"

People are afraid that bricks on the reaction wheel will fly off when it spins really fast, then hit them in the gut. This provides comfort, and maybe even some protection

Interesting blackboard observation

Cable routing

Much prettier than in Toronto. Partly because we were neater, and partly because there's no more chicken wire

Crane controls

Helps show why only trained personnel operate this crane

Anti-rotation device

High above, the beginnings of the pivot anti-rotation device are installed. Named "broomstick" after the alternate solution of duct taping a broomstick across

Ziggy holds the fill tube

During a liquid helium fill

Jon operates the dewar end

And Jamil gets to operate the cryostat end

You can see he's excited for his first helium fill

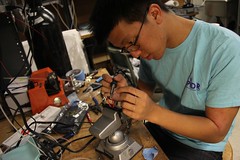

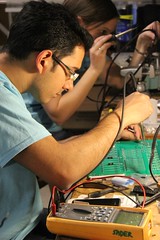

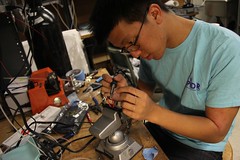

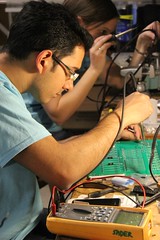

Solder party - with Spider T-shirts!

This kept us occuied for several days

Anne adjusts a backshell

Ed solders

Jamil mostly works on the circuit board

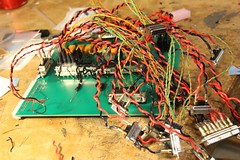

For the inner-frame power breakout (IF PBOB)

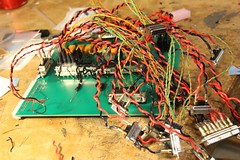

Finished IF PBOB

And its amazing "hairdo"

The result of three days' work

A pile of cables

Princeton highbay panorama

With gondola and cryostat in the same room for the first time!

I’m happy we are switching from chicken-wire to wood boards!