Team Toronto (plus Don) spent yesterday conducting a Bemco (thermal/vacuum) test.This mainly involves waiting around while temperatures or pressures change very slowly. And occasionally making sure nothing has broken. As such, I took occasional sanity breaks and visited everybody else.

The cryo team had finished with the telescope inserts and was closing up the vapour cooled shields (VCS). These are shells within the cryostat cooled by helium boil-off and insulated with many layers of aluminized mylar (aka MLI: multi-layer insulation).

Bemco, ready to close

Power wiring

After having gone through the vacuum bulkhead

Bemco in progress

Looking through the window. The chamber's a float pressure now (0.5% atmosphere)

Important gadget

Once under vacuum, this highly calibrated piece of scrap metal holds the latch open. Then when pressure builds, the door will open rather than the chamber exploding

Don fixing a computer

It needs a fiber optics card replaced

Becky cleaning

All of the cryostat parts need cleaning before insertion

Anne doesn't think that cleaning, taping, and bolting are "science"

The science sign disagrees

Johanna and Becky covering the center hole of the shield

Spanky

Sasha finishes up the back of the cryostat

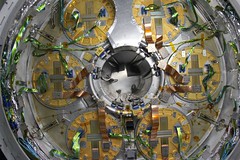

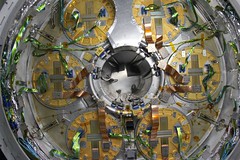

Fully loaded Spider

Actually, one of the inserts is a lie. Can you spot which one?

Ziggy, double thumbs-up

Flexible heat straps

Providing 4K and 1.4K to each insert

Complete back of one insert

Jon documenting

Presumably in a studied manner, not my ignorant snapping

Kevlar straps

To catch the tank if things break when the payload lands

Center tube

Used for wiring

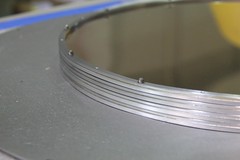

Outer edge of the cryostat

Contains multi-layer insulation ("MLI", many layers of shiny aluminized mylar) and cables

The capillary

Transports liquid helium between the main tank and the superfluid tank

Sasha tapes the edges of a filter stack

The filters reflect unwanted light, to prevent it from warming the cryostat

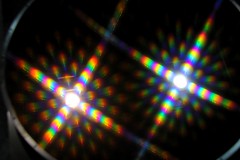

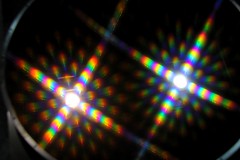

The stack. Stacked

Reflections of overhead lights in the filter

The surface is a finely-patterned metal mesh. You can distinguish filters by their reflection pattern

Reflections of overhead lights in the filter

The surface is a finely-patterned metal mesh. You can distinguish filters by their reflection pattern

Top of cryostat

With metal base of vapour-cooled shield (VCS) (cooled by boiling helium vapour)

Group action shot

At the VCS on the bottom

Anne and the VCS

Preparing to install the MLI layer

Very flattened bug

Found on crane cable

Applying MLI to the top VCS

MLI'd and filtered top

The state at the end of the day

Leave a Reply